Whole Room and Targeted Disinfection

Whole Room Disinfection

Whole-room disinfection replaces the traditional method of spraying disinfectant on surfaces and wiping them down, which is both labor-intensive and unreliable. It works by aerosolizing the disinfectant so it kills bacteria not just on surfaces, but also in the air, and in hard-to-reach cracks and crevices.

The most effective and affordable whole-room systems create a fog that fills the entire space being treated without wetting any surfaces, while still killing up to 99.9999 percent of the hardest-to-kill germs.

Targeted Disinfection

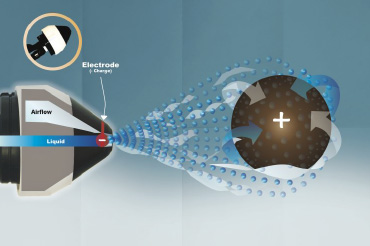

Any public facility can be the source of pathogen transmission. Enhanced targeted room disinfection strategies are necessary in our modern landscape in order to protect patients and staff, but also to mitigate the risk of our target pathogens developing antimicrobial resistance. Electrostatic spraying systems coupled with sustainable EPA approved solutions should be the future of our disinfection efforts. Cleaning and disinfecting surfaces, objects, and electronics has never been easier than with Safety Net’s lineup of sprayers and solutions.

Highly vetted and rigorously tested equipment and solutions that are rooted in scientific evidence are a staple of our targeted room disinfection product lineup. Utilizing techniques and technologies that have been evolving over the scope of time, much in the way microbes change and adapt, Safety Net is actively advocating and looking for solutions that are built around this philosophy of adaptation.

Electrostatic Spraying Can Provide Both Whole Room, and Targeted Disinfection.

Take control of your environment by merging the power of electrostatic spraying systems with sustainable, non-toxic, safe-to-use, healthcare-grade solutions. Explore our sprayers, cleaners, disinfectants, and antimicrobials below.

Benefits of Electrostatic Spraying

- Safer for workers, students, and others in the area: Low volume electrostatic spraying means less chemical exposure for everyone.

- More effective than spray and wipe: The small droplet size and improved coverage substantially improves the bioavailability of disinfectant compounds.

- Fewer sick days: Routine Disinfection limits transmission of many communicable diseases including bacterial infections, influenza, and other viruses, and digestive diseases such as the Norwalk virus or salmonella.

- Less toxic chemicals can be used: The increased effectiveness allows more choices for disinfection and sanitization.

- Better for the environment: By using safer chemicals and reducing waste, the total environmental load is substantially lightened.

Electrostatic Sprayers for Agriculture

ESS air-assisted electrostatic sprayers produce droplets 900 times smaller than those produced by conventional or hydraulic sprayers. After tiny droplets are atomized they are then given an electrical charge they are carried deep into the plant canopy in a turbulent air-stream. The result provides more than twice the deposition efficiency of traditional hydraulic sprayers and foggers.

Better spray coverage equates to lower chemical consumption and faster investment payback. Most growers can reduce chemical costs by 25-50% and still see effective results from their spray program. ESS sprayers are the answer for combating some of the worst agricultural problems like thrips, aphids, downy mildew, mealybugs, early blight, late blight, and listeria. The electrostatic spraying combined with less chemicals can also give you excellent results when trying to control weeds and other unwanted plant growth.

Cleaners & Disinfectants

By definition, Cleaning removes dirt, dust, debris, and biofilm from surfaces or objects using a mild cleaning product and a cloth to physically clean off the surfaces and objects. This may not necessarily kill the germs, but it lowers their numbers and the risk of spreading infection. Although sanitize and disinfect are often used interchangeably, there is a significant difference between the two.

Sanitizing lowers the number of germs on surfaces or objects, either by killing them or removing them through chemical processes to a safe level, as defined by public health standards.

Disinfecting on the other hand goes beyond both Cleaning and Sanitizing and follows the CDC guidelines to properly remediate to a minimum of a 99.9% efficacy level using liquid chemicals or wet pasteurization that allow microorganisms to die off within 30 seconds of application. Given that each surface contains millions of microorganisms, cleaning and disinfection offers the best solution to eliminate pathogen and prevent cross-contamination.