The concept of Nanotechnology which has been around for quite some time now. It focuses on the design and manufacture of extremely small devices and structures and has been utilized in a variety of industries such as electronics, medicine, energy, textiles, weapons, and more. Nanotechnology can be used to create materials, devices and systems with unique properties and function. The very small size of the materials allows them to exhibit different physical and chemical properties than the same materials at a larger scale.

With greater emphasis being placed on clean water sources, nanotechnology is providing critical contributions to agriculture in a variety of ways. With the evolution that is taking place in agriculture and the need for better technology for the treatment of water, nanomaterials can be used to create more effective filters for removing contaminants from water. Nanotechnology can cost-effectively treat contaminants in water that are untreatable by conventional methods. Bacteria, viruses, and heavy metals, which cause 1.5 billion people world-wide to suffer from water-related diseases each year, can be treated more efficiently with nanotechnology.

With the successes being achieved in agriculture with nano-enabled water treatment methods, we are now able to go even further with the introduction of Nanobubble technology. Nanobubble technology has brought about a whole new frontier of science and engineering that is changing how entire industries utilize and treat their water. This revolutionary technology and the fundamental understanding of nanobubbles is continuously evolving with recent advancements in nanobubble production methods and ongoing discoveries around how to measure, manipulate, and apply nanobubble properties to solve customer problems.

What are Nanobubbles

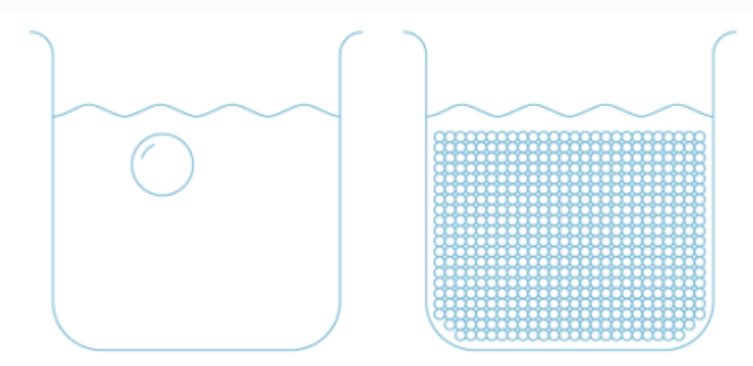

Nanobubbles are nanoscopic gaseous molecules that are ten thousand times smaller than a human hair and have the ability to change the normal characteristics of water. Ordinary bubbles have a diameter around 1 μm or larger. Nanobubbles which are smaller than 100 nm in diameter will randomly drift in a manner known as the Brownian Motion and can remain in liquids for extended periods of time.

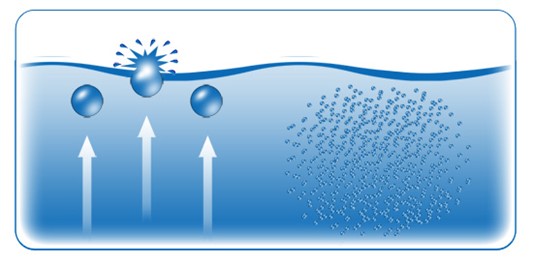

Nanobubbles behave differently from larger bubbles because they are nanoscopic. All of their beneficial attributes, stability, surface charge, neutral buoyancy, oxidation, etc. are the result of their size. These unique features enable nanobubbles to participate in physical, biological, and chemical reactions while also providing the most efficient gas transfer. Unlike larger size bubbles that increase in size, rise rapidly, and burst at the water surface, nanobubbles remain stable in water for an extended period of time due to their strong negative surface charge and neutral buoyancy.

Nanobubbles are neutrally buoyant and can remain suspended in water for weeks without rising to the surface. They have a strong negative surface charge that keeps them stable in liquid and enables them to continuously participate in and stimulate physical, biological, and chemical interactions. When nanobubbles are stimulated, they destabilize and collapse, releasing the hydroxyl radical. The hydroxyl radical (HO) is one of the strongest known oxidizers commonly used to destroy hard to treat and hard to kill contaminants in water.

Nanobubbles have been studied for a wide range of applications, including water treatment and drug delivery, but have also been investigated for use in enhancing various industrial processes, such as cleaning, food processing, and oil recovery. The longevity factor of nanobubbles in water increases residence time of oxygen in the water and in doing so, directly impacts any type of aerobic or anaerobic interaction with viruses and bacteria.

Benefits of Nanobubbles

There are a number of benefits with Nanobubble technology that promises to redefine everyday processes by establishing a new standard for efficiency and sustainability:

- Increases oxygen levels in water.

- Can significantly eliminate microbial biofilms on surfaces.

- Boosts dissolution efficiency and extends retention time.

- Lowers surface tension, enhancing fluid permeability.

- Will burst with ultrasound and kill bacteria.

- Will be enhanced in combination with chlorine-based sanitizers

- Stays stable in liquids until interaction with surfaces or contaminants occurs.

- Amplifies sanitizer delivery to bacteria.

- Effectively eradicates microbial biofilm on surfaces, even within pipe interiors.

- Utilizes a strong negative surface charge to prevent coalescing and separate small particles.

A New Addition To Biosecurity

SafetyNet’s Aquaox Hypochlorous Acid solution (HOCL), part of our Enhanced Biosecurity Program, contains a high concentration of Nanobubbles of chlorine-oxygen in the treated water. These “colloidal particles” exhibit all the characteristics of a colloidal dispersion and will influence the nature and extent of any interfacial behavior of that bulk water.

Besides changing the chemical properties of water, the unique electrolysis technology of the Aquox product restructures the water by generating trillions of small bubbles to deliver remarkable features that ordinary bubbles do not possess. Aquaox Nanobubbles are electrically charged and stay suspended in liquids for months to accelerate the growth of plants, prevent biofilm and mineral scale formation, improve filtration, solubility, detergency, and lubricity properties of Aquaox solutions.

When HOCL-Nanobubbles are triggered, they destabilize and collapse releasing the Hydroxyl radical. The Hydroxyl radical (OH-) is a three-electron reduction product of molecular oxygen and the most reactive species of oxygen. It is one of the strongest known oxidizers commonly used to destroy hard-to-kill pathogens, destabilize biofilms, and penetrate the smallest cavities in surfaces deeply removing all contaminants.

With so much emphasis on reducing and eliminating the use of pesticides on plants, there is also the issue of excessive application of chemical fertilizers which can lead to serious environmental problems as well. There has been a great deal of research around the use of nanobubbles in water for irrigation as a means of reducing fertilizer use. It has been proven that Nanobubbles can have a positive effect on plant growth and nutrient uptake, while providing better crop yield and the efficiency provided by fertilizers.

The Next Generation Product

With all the benefits the Nanobubble technology brings to bear that can revolutionize so many industries, especially the treatment of water, Aquaox has taken this to a new level with the introduction of their new Nanobubble Generator. The technique utilized by the Nanobubble Generator consistently produces high density solutions of optimally sized nanobubbles, averaging 100 nm in diameter and ranging between 50 and 100 nm.

The unique, patented technology utilized combines three fluid mechanic principals to produce a high concentration of stable, extremely small size nanobubbles without the need of any external gasses. Nanobubbles of this size are stable in liquid because they have reached equilibrium with bubble surface tension, internal pressure, external pressure, surface charge, and their environment. Their stability and size give them neutral buoyancy and remain suspended until they interact with surfaces or contaminants.

The Aquaox Nanobubble Generator has a superior ability to blend gas and liquids into a stable solution with consistent particle distribution. It produces a large number of nanobubbles with a strong negative surface charge which allows them to attract an remove dirt. By using nanobubbles, you can reduce the number of detergents and solvents used for cleaning.

Creating The Gold Standard For Nanobubbles

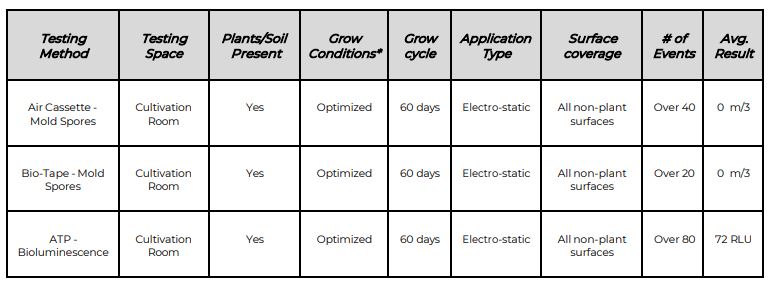

Aquaox products are known around the world for their efficacy, reliability, and proven results. Their efforts to advance the science of nanobubbles and push the industry standards have been tested by third-party experts to validate the efficacy of their nanobubble technology.

Simply put, nanobubble technology supersaturates irrigation water with dissolved oxygen and injects hundreds of millions of electrochemically charged nanobubbles, which alters the properties of water.

Increased dissolved oxygen levels maximize oxygen utilization by plants and beneficial microbes in the rhizosphere, promoting healthy root development and improving plants’ resilience to environmental stressors such as drought and heat.

The end result is a technology that when used consistently as part of a proper irrigation system has proven to reduce fertilizer needs, produce more robust root systems and more resistance to pathogens and disease. This provides improved yields, shortens crop cycle times, and reduces disease pressure creating bigger, healthier plants with even more end product to use.

Using nanobubble technology as a chemical-free, cost-efficient, sustainable way to solve known problems helps to lower inputs, whether chemical, energy, or material, which saves cultivators money, and makes the crops more sustainable and environmentally responsible.

Time To Embrace The Technology?

Time To Embrace the Technology

Nanobubble technology is becoming increasingly popular in a range of aquaculture operations, with a growing number of studies supporting their value, both in improving production and in reducing the environmental impact of so many industries.

It is time to be a pioneer in safeguarding your products, consumers, and your bottom line. Take part in this extraordinary journey and elevate your business, with cost-effective sustainability and embrace a future where nanobubbles propel enhanced performance in diverse industries.

Take the first steps towards a healthier, more prosperous future for your cannabis venture and join the growing number of people who are shaping the future of cannabis industry. Contact SafetyNet today at info@safetynetamerica.com to discover how we can help empower your cannabis business with this great new technology.