Although Electrostatic Spray technology has been used extensively in outdoor settings, it has drawn increased interest because of its effectiveness when disinfecting large indoor spaces or areas (e.g., schools, offices, businesses, agricultural spaces, etc.) with many surfaces. Electrostatic spraying is essentially a method of applying a complete coating of a cleaner, or chemical disinfectant, or other liquid. It involves applying an electric charge within the sprayer to the chemical disinfectant liquid to get it to fully cover any surface it is sprayed on.

The result is a more cost-effective and time-efficient process with numerous advantages. It is worth understanding how electrostatic spraying works and why it is the best and most advantageous disinfection and sanitization method to use to get the most out of your cleaning protocols and processes. Selecting the right sprayer for your environment is important for optimizing transfer efficiency. The challenge is choosing one that maximizes the spray performance for your specific application.

What Is Electrostatic Spraying

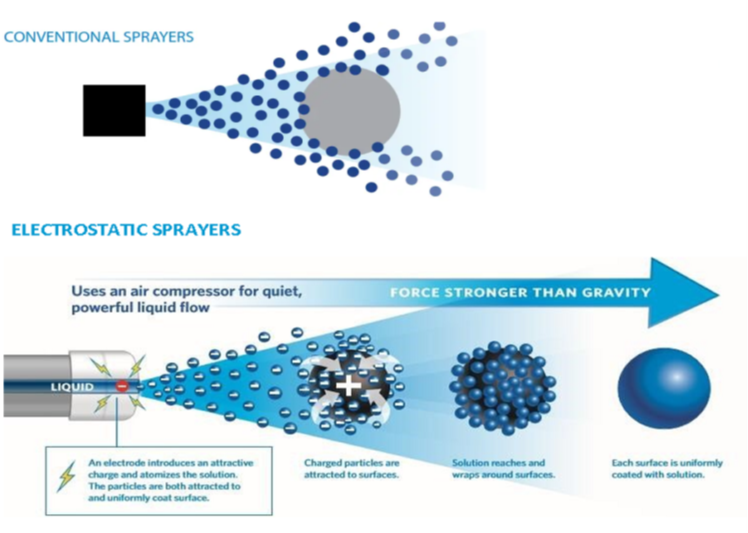

Unlike conventional spraying methods, electrostatic sprayers apply a negative charge to liquid disinfectants as they pass through the nozzle. The negatively charged disinfectant is attracted to positively charged surfaces, which allows for efficient coating of hard nonporous surfaces with far less product being used.

The electrostatic spraying technology uses the concept of “The Wrap Around Effect”. This means it can surround and cover objects completely from front to rear, top to bottom, and in every nook and cranny which allows for disinfection of those areas where you could not reach otherwise, substantially improving the scope of disinfection. Because of this Wrap Around effect, electrostatic sprayers can coat any surface or product with even coverage all around. When you think about the concept and process of disinfecting, electrostatic spraying is the most effective solution.

Adoption of Electrostatic Spraying as a Standard

In 2020, the EPA released guidance for adding electrostatic sprayer application directions to disinfectant product labels for use against SARS-CoV-2 (EPA takes action to help Americans disinfect indoor spaces efficiently and effectively | US EPA). This came after numerous studies that show that electrostatic spraying is far more effective in every way when compared to conventional sprayers when applying disinfectants over large areas or complex, intricate surfaces. This has been confirmed with a more recent post from the EPA (Evaluating Electrostatic Sprayers for Disinfectant Application | US EPA) where they confirm what was previously stated.

The Power of Superior Products

When looking at electrostatic spray technology, one company, Electrostatic Spraying Systems (ESS), stands out from the rest providing superior products world-wide. ESS has been in the business of manufacturing electrostatic sprayers utilizing its patented and proprietary technologies for over 30 years. Today, customers in over 60 countries worldwide enjoy the benefits of applying a variety of water-based disinfectants, food safety solutions and agricultural products with peace of mind that they are saving both time and money.

SafetyNet’s partnership with ESS allows us to offer a wide variety of electrostatic sprayers that provide the best electrostatic charge and consistent droplet size for superior coverage and when combined with our Enhanced Biosecurity Program has shown the highest pathogen reduction rate when used properly and consistently.

ESS sprayers take advantage of the principle of physics to achieve better coverage and to lessen the environmental impact by allowing smaller amounts of chemicals to be used. ESS sprayers are designed to impart an electrostatic charge to the spray droplets as small as 30 microns, with the goal of increasing deposition of the droplets onto surfaces, thereby promoting more efficient use of the disinfectant with less waste. Testing by four major universities comparing ESS sprayers with conventional and air-blast sprayers shows 300% better spray penetration and coverage.

The heart of the air-assisted electrostatic sprayers from ESS is the MaxCharge™ “air-atomizing induction-charging” nozzle, which was invented and patented, at the University of Georgia.

Air is necessary in electrostatic spraying to create tiny droplets (30-60 microns, 900 times smaller than conventional sprayers) that can travel in the turbulent airstream into dense areas.

Custom industrial applications engineered by ESS utilize electrostatic technology solve spray problems in areas like:

- Food Safety

- Food Processing

- Animal Health

- Industrial Coating

- Post Harvest

- Commercial and Industrial Vehicle Sanitizing

ESS offers an extensive line of sprayers for almost any industry with everything from small garden sprayers to large row crop units. ESS sprayers are the answer for combating some of the worst agricultural problems like thrips, aphids, downy mildew, mealybugs, early blight, late blight, and listeria. Electrostatic spraying combined with less chemicals can also give you excellent results when trying to control weeds and other unwanted plant growth.

The technology behind the ESS line of sprayers has proven to use significantly less water and get better coverage. The savings from this alone have the potential to pay for the cost of most sprayers in a relatively short period of time.

The ESS line of portable and outdoor sprayers is the ideal solution for biosecurity, fighting Coronavirus Disease (COVID-19), MRSA, E. Coli, salmonella, swine flu, C. Diff, H1N1, and various other bacteria and viruses. The wide variety of sprayers available when combined with the superior disinfectants and antimicrobial products like those available in our Enhanced Biosecurity Program, reach into every nook and cranny of an environment to find and destroy pathogens where they hide.

ESS also offers an extensive line of large row crop agricultural sprayers for most growers’ needs. The air-assisted electrostatic sprayers produce droplets 900 times smaller than those produced by conventional or hydraulic sprayers. After tiny droplets are atomized, they are then given an electrical charge that is carried deep into the plant canopy in a turbulent airstream. The result provides more than twice the deposition efficiency of traditional hydraulic sprayers and foggers.

Conclusion

Research on electrostatic spray technology has both a natural basis and practical significance. The utilization of electrostatic spray technology has covered the biological, food, pharmaceutical, industrial, agricultural, chemical, and manufacturing industries.

Electrostatic spray technology is the best way to apply cleaners, sanitizers, and disinfectants to help facilities treat surfaces, often in less time and with better coverage than traditional cleaning methods and devices. Electrostatic technology is not new, with a history of more than 60 years in areas including business, schools, agriculture, automotive, and many other industries.

Routine cleaning, disinfection, and protection should continue to be a top priority to protect any facility against pathogens. Utilizing electrostatic technology in these processes can drastically cut down on the amount of time spent disinfecting.

With electrostatic technology and the extensive variety of sprayers offered, you will be able to complete a more thorough, consistent disinfection process given the product’s ability to entirely cover surfaces and objects, and will reduce overusing disinfectants, which saves your company money on products.

Ready to Evaluate Our Electrostatic Products?

Contact SafetyNet today at info@safetynetamerica.com and use discount code SNESS20 to receive your discount and discover how our electrostatic sprayers can empower your business. Gain access to valuable insights, proven strategies, and a roadmap to cleaner, pathogen-free environments.

Be a pioneer in safeguarding your environment, products, consumers, and your bottom line. Take the first steps towards a healthier, more prosperous future for your business.