Introduction

Cannabis consumption has surged in recent years due to its medical and recreational legalization in many regions. However, with the increased production and distribution of cannabis products, there has been a growing concern about the potential for contamination.

Contaminated cannabis products can pose severe health risks to consumers, leading to adverse effects such as respiratory and gastrointestinal illnesses. Addressing this issue requires innovative solutions, and one promising approach is the utilization of residual antimicrobial products on cannabis packaging.

The Problem of Contaminated Cannabis Products

Cannabis, like any agricultural product, is susceptible to contamination during various stages of cultivation, processing, and distribution. Contaminants can include bacteria, fungi, molds, heavy metals, and even chemical residues from pesticides or fertilizers.

According to a New York Times article from December, “lab tests conducted on smokable weed, edible candies and vaporizers purchased from 20 smoke shops and dispensaries detected prohibited levels of eight different contaminants, including E. coli, salmonella, nickel and lead.”

Another article published in Marijuana Moment stated, “Leung’s team noted a total of 679 contaminants regulated by at least one of the 36 states with legal cannabis: 551 pesticides, 74 solvents, 12 inorganic compounds, 21 microbes, 5 fungal toxins and 16 other contaminants. Yet only 23 of those states regulated all four categories of contaminants: pesticides, inorganics, solvents, and microbes/mycotoxins and noted the action level for each contaminant.”

Contamination is not limited to the environment that these products are grown in but can occur at multiple points like transportation, storage, and post-packaging. According to a study on the microbial spoilage of vegetables, fruits, and cereals found, “the packaging conditions and material influence the microbiological quality of processed produce.” Using a controlled or modified atmosphere for packaging conditions is a commonplace practice in most commercial settings. “Advances in the type of packaging material, and other strategies such as those that ensure the removal of void-space (space not occupied by food particles) have helped to override this disadvantage to a certain extent to extend the shelf life of food products (Jacxsens et al., 2001).”

The void-space within a package creates the perfect environment and breeding ground for dormant pathogens to come alive and cause contamination. Current strategies use gassing procedures to create a modified atmosphere packaging solution, but even with these current processes, contamination still poses a threat.

Having poor packaging solutions can jeopardize public health, and contaminated cannabis products can damage the industry’s reputation and lead to legal and financial consequences for producers and distributors. We know from previous articles about how Biotrexx 247 works for agricultural environments and products as a substitute for pesticides, but an often-overlooked use case for this incredible solution is as a pre-treatment and coating on packaging products before cannabis is introduced.

Mode of Action of Biotrexx 247

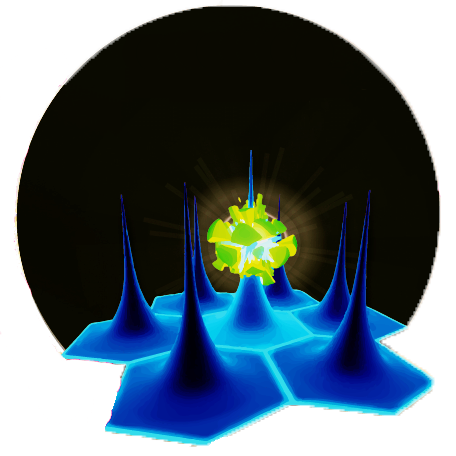

The effectiveness of Biotrexx 247 in inhibiting microbial growth lies in its unique mode of action, which is an electrochemical mode of action. The active ingredient in Biotrexx 247 antimicrobial forms a colorless, odorless, positively charged polymer, which chemically bonds to the treated surface. Think of it as a layer of electrically charged swords that stays on the interior lining of a package for days to weeks at a time.

When microorganisms encounter the treated surface, a “sword” (carbon chain) punctures the cell membrane. Then the electrical charge shocks the cell. Due to the electrical shock being transferred to the now dead cell, the “swords” maintain their strength and are ready for the next cell to contact it. This disruption prevents microbial survival and replication, thereby reducing the risk of contamination on cannabis products stored within treated packaging.

Another huge benefit of Biotrexx 247 is its ability to pull microbes and pathogens out of the air through the positively charged polymer. We spoke earlier about void-space and how that presents an opportunity for pathogens and microbes to permeate within a package, however, when Biotrexx 247 is applied to the package, it keeps the void-space clear and free of microbes by attracting them to the “swords.”

Long-Lasting Protection

One of the significant advantages of utilizing Biotrexx 247 on cannabis packaging is its long-lasting protection and agnostic application. Unlike conventional disinfectants, which offer temporary solutions, Biotrexx 247 forms a residual antimicrobial layer on the surface of the packaging material through a Silane quaternary bonding agent.

This layer continues to provide protection against pathogens for an extended period, from the point of packaging until the product reaches the end consumer. The sustained antimicrobial effect of Biotrexx 247 can significantly reduce the chances of contamination during storage and transport, ensuring that consumers receive safe and uncontaminated cannabis products.

Compatibility and Safety

Internal studies have demonstrated that Biotrexx 247 is compatible with various types of packaging materials commonly used in the cannabis industry, including glass, paper, plastic, and metal. A lot of cannabis packaging material is thick and a huge benefit of Biotrexx 247 is its unparalleled ability to bond to these thicker materials.

A publicly available study from 2017 on this product concluded, “Overall, the results of our study showed that the silane QAC coating technology has antimicrobial activity against Gram-positive bacteria even in the presence of repeated washing while it showed moderate activity to Gram-negative bacteria.”

Biotrexx 247 has also been extensively tested for safety and has been approved by the FDA and EPA for use in the healthcare, food, and pharmaceutical industries.

Conclusion

The growing demand for cannabis products calls for enhanced safety measures to minimize the risk of contamination. Utilizing residual antimicrobial products, such as Biotrexx 247, on cannabis packaging presents a promising solution to this pressing issue. Integrating this technology into cannabis packaging processes is simple and packs a big punch.

Scientific research has shown that Biotrexx 247 effectively inhibits the growth of harmful pathogens on numerous surface types, providing long-lasting protection and ensuring the safety of cannabis consumers. As the industry continues to evolve, embracing innovative technologies like residual antimicrobial packaging will play a crucial role in reducing cases of contaminated cannabis products, protecting public health, and fostering consumer confidence in the cannabis market.

About the Author

Robert Hasselfeld is a freelance writer and web developer for Safety Net, LLC.